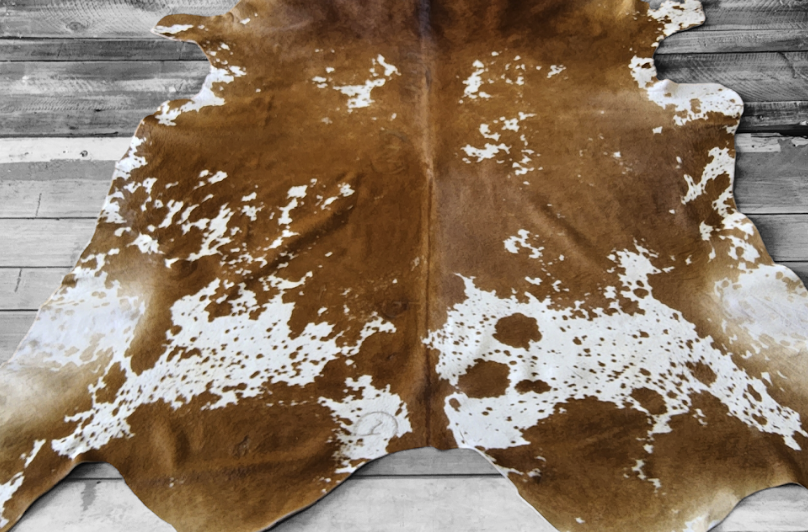

Discovering the Journey of Cowhides: From Ranch to Remarkable Creations

Some folks may raise concerns about cattle ranching for leather and custom furniture, but let’s delve into the process to gain a deeper understanding. The truth is leather is a valuable by-product of the cow’s meat, using more of the animal and minimizing waste. Contrary to misconceptions, harvesting a cow solely for its leather would be unprofitable and impractical for ranchers.

Now, let’s take a captivating look at the intriguing journey of how cowhides are harvested and transformed into exquisite leather goods.

The First Step: Raw Material Collection Cattle hides are a natural by-product of the beef industry. During a cow’s life on the ranch, it may encounter various elements like barbed wire, insects, reptiles, branding, and more, resulting in blemishes on the hide. These imperfections reduce the amount of usable leather from each hide. Tanners consider hides with 80-90% usable leather as “quality,” while those yielding 60% or less are considered “sub-quality” but can still be used for smaller items like keychains and gloves.

Preparing the Hides for Tanning After the hides are collected, they are sent to tanneries to undergo preparation for tanning. This process involves soaking, unhairing, fleshing, deliming/bating, and pickling. Tanneries carefully treat the hides to remove any chemicals and adjust the collagen’s PH level before they are ready for tanning.

The Transformation: Tanning The tanning process, aptly named after tannic acid, plays a vital role in turning cowhides into leather. Tannic acid displaces water from the protein fibers in the hide, cementing them and making the leather more resistant to bacterial and fungal enzymes. This essential process imparts durability to the final leather product.

Diverse Tanning Techniques There are 3 main tanning techniques, each suited for different types of leather products:

- Vegetable Tanning: An ancient and all-natural process involving tree bark, olive leaves, and Rhubarb roots, creating firm and water-resistant leather. While it represents a smaller portion of the leather market, vegetable-tanned leather is considered luxurious and is used in premium items like saddles, boots, wallets, and holsters.

- Mineral Tanning: Using mineral salts, this technique produces softer and more pliable leather with a shorter tanning process compared to vegetable tanning. Chromium salt is the most commonly used agent, but aluminum and zirconium salts are also employed.

- Oil Tanning: This ancient method uses fish or other oils to replace the natural moisture in a dried hide, creating soft and porous leather. Oil tanning is often used for chamois leather, known for its ability to withstand repeated wetting and drying without damage.

Adding Color; The Dyeing Process: Once the leather pelts are thoroughly dried, they are ready for dyeing. Various techniques like dip dyeing, spray dyeing, or brush dyeing are employed to infuse the leather with vibrant colors. Each method has unique benefits, from efficiency to preserving the leather’s delicate qualities.

1. Leather Dip Dyeing – Dip Dyeing is a common tannery leather dyeing technique. The pelts are introduced into a drum and soaked in leather-dye water. To increase the penetration, the temperature inside the drum is raised to 50-60 degrees Celsius. The drum is also rotated to help improve the penetration of the leather dyes.

2. Leather Spray Dyeing – In tanneries, spray dyeing is a valid alternative to dip or drum dyeing. It’s generally carried out using a special machine consisting of a carousel rotary with spray guns that rotate and spray leather dye simultaneously on the leather. The spray dyeing technique has considerably shortened production times. It is a very rapid process and requires very little employment of labor.

3. Leather Brush Dyeing or Sponge Dyeing – In tanneries, this dyeing technique is used when it is necessary to color more delicate leathers. The production of gloves is a good example. Maintaining the leather’s softness is important, which the dyeing drum’s harsh action could alter. The process involves an operator laying out the leather on a table. The leather dyeing is then accomplished by using a horsehair brush, which is dipped in the leather dye and then applied to the surface of the leather. This artisanal leather coloring technique is still used today in some tanneries, but only for producing fine leather products. As you might guess, the cost of this process is very high.

The Grand Finale: The Finishing Process The final step involves adding a specific shine and color to the leather, protecting it, and enhancing its look, feel, and strength. This process adds the perfect finishing touch to the leather goods, making them ready to be cherished and enjoyed.

Question is, WHERE do you find REAL custom cowhide furniture? Visit our friends at Ranch & Co. Interiors!

Discover the Beauty of Custom Cowhide & Fine Leather Furniture. If you’re intrigued by the allure of cowhide, we invite you to explore our sister company, Ranch & Co. Interiors. Their expertise in genuine, high-end cowhide and leather goods is unmatched, and we’re proud to incorporate cowhide into our products at The Original Windmill Ceiling Fan Company.

And the cherry on top? At The Original Windmill Ceiling Fan Company, we’ve recently incorporated cowhide into our products, including custom cowhide framed photography AND the option to wrap your Windmill Ceiling Fan motor in the finest cowhide leather or cowhide print!

Trust us; it’s a design statement that will leave your guests in AWE!

Meanwhile, our fans AND custom cowhide picture frames are hand-cut, hand-assembled, and hand-packaged at our Pilot Point, Texas warehouse, where we deliver a unique look and feel and unrivaled strength and craftsmanship.

We are the only windmill ceiling fan supplier with custom fans matching your personality and style!

Why Choose Us?

- Quickly match the fan finish to your home’s decor

- Experience a unique look and feel

- Not mass-produced – every piece is special

- Proudly made in North Texas

- Damp-rated for durability and performance

Make your home a reflection of your personality and style. Call us today at 972-834-5555 or visit www.windmillceilingfans.com to explore the exquisite world of cowhide furniture and windmill ceiling fans. Get ready to be captivated!